The Tallest Public Bridge Observatory in the World

The Penobscot Narrows Bridge is a cable-stayed bridge over the Penobscot River in Prospect, Maine. It replaced the Waldo-Hancock Bridge, which was built in 1931.

The Penobscot Narrows Bridge began construction in May 2003, built by Reed & Reed, Inc. / Cianbro Joint Venture. It was completed in 2006 and as of 2024 is the tallest public bridge observatory in the world.

The bridge's observatory offers breathtaking panoramic views of the surrounding area, including the Penobscot River and the beautiful Maine landscape. Visitors can enjoy the stunning scenery from the observatory's glass-walled elevator or the outdoor observation deck.

Image from Reed & Reed

Image from Lawrence Techincal University

Figg Cable-Stay Cradle System

The Penobscot Narrows Bridge features a unique cable system. It uses a Figg Cable-Stay Cradle System. This allows cables to be "easily" replaced, which in turn provides an opportunity for experimentation.

The following groups all worked together to install the experimental carbon fiber composite cable strands (CFCS) on the bridge:

Maine DOT | FHWA | University of Maine | Figg Engineering Group | Lawrence Technical University | Tokyo Rope | CTL Group | Reed & Reed / Cianbro

They installed experimental carbon fiber composite cable strands (CFCS) on the bridge. The CFCS were installed at stays 2, 10, and 17 on the north pylon, with 2 CFCS per stay.

It is important to note these are non-structural (extra cables), and do not affect the structural integrity of the bridge.

The CFCS strands are monitored using a structural health monitoring system that includes sensors to measure CFCS strand force, changes in strain, load-chair deflections, and temperature at the anchorage locations and exterior.

The Purpose of the CFCS

The reasoning behind the installation of the CFCS was to study the long-term behavior and durability of CFCS in a real-world cable-stayed bridge application. The Penobscot Narrows Bridge serves as a safe place to gather real world data on the CFCS.

The Carbon Fiber Composite Strands are manufactured by Tokyo Rope Co. of Japan and are composed of six helically wound rods wound over a central rod, bound in epoxy resin. The anchorage system for these cables a threaded socket and an anchor nut.

Steel strands are typically used in cable-stayed bridges, but CFCS offer potential advantages such as higher strength-to-weight ratio, corrosion resistance, and ease of installation. Carbon Fiber is also very lightweight. Maintence related to corrosion alone costs the U.S. approximately $276 billion, yearly. The data gathered from this effort may prove carbon fiber as a more viable material for infrastructure, as opposed to steel, then a lot of taxpayer money can be saved.

Top Image Lawrence Techincal University

Bottom Image from University of Maine

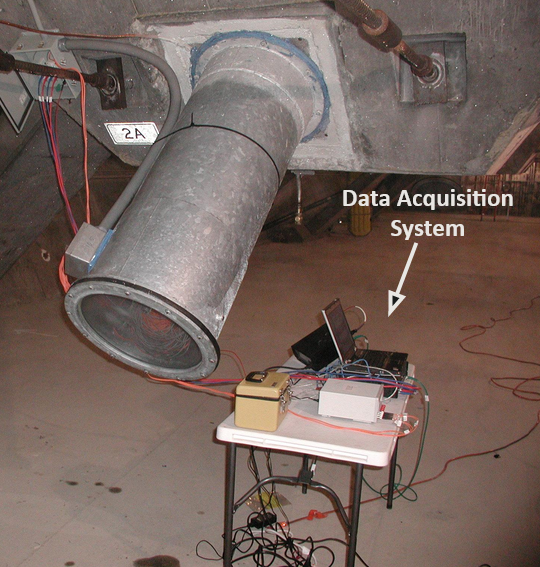

Image from inside PNB

Structural Health Monitoring System

A structural health monitoring system was implemented to monitor the CFCS strands over the long term. The monitoring objectives are to detect variations in force and strain on the CFCS at the anchorage locations and correlate the measurements with ambient temperature.

The monitoring system includes sensors to measure:

- CFCS strand force using load cells at the strand anchors

- Changes in strain using fiber optic strain (FOS) sensors attached to the strands

- Load-chair deflections using displacement transducers (LVDTs)

- Temperature at the anchorage locations and exterior

The data from these monitoring systems is transmitted to the pylon base of the bridge through Fiber Optic Cables to a receiver. This receiver then communicates with a Computer hooked up to a WSDA Basestation, allowing for wireless transmission. Data is then transitted from the Data Acquisition System to a Google Drive.

Long Term Goal

The long-term plan is to continue monitoring the CFCS strands to assess their performance and durability over time. Recommendations include transitioning to a continuous online monitoring system for both the CFCS and steel strands.

In summary, the Penobscot Narrows Bridge is serving as a "living laboratory" to study the long-term behavior and durability of CFCS in a real-world cable-stayed bridge application, enabled by the unique cable system and the comprehensive structural health monitoring system that has been implemented.

Image taken by Team ZATAN

Keith Berube, Ph.D., P.E

keith.berube@maine.eduAssociate Professor at the University of Maine, Department of Mechanical Engineering

Roberto Lopez-Anido, Ph.D., P.E.

RLA@maine.eduProfessor of Civil & Environmental Engineering at the University of Maine, Department of Civil and Environmental Engineering

Andrew J. Goupee, Ph.D.

agoupe91@maine.eduAssociate Professor at the University of Maine, Department of Mechanical Engineering